Products |

Product Details

当前位置:

Home>

Product Details

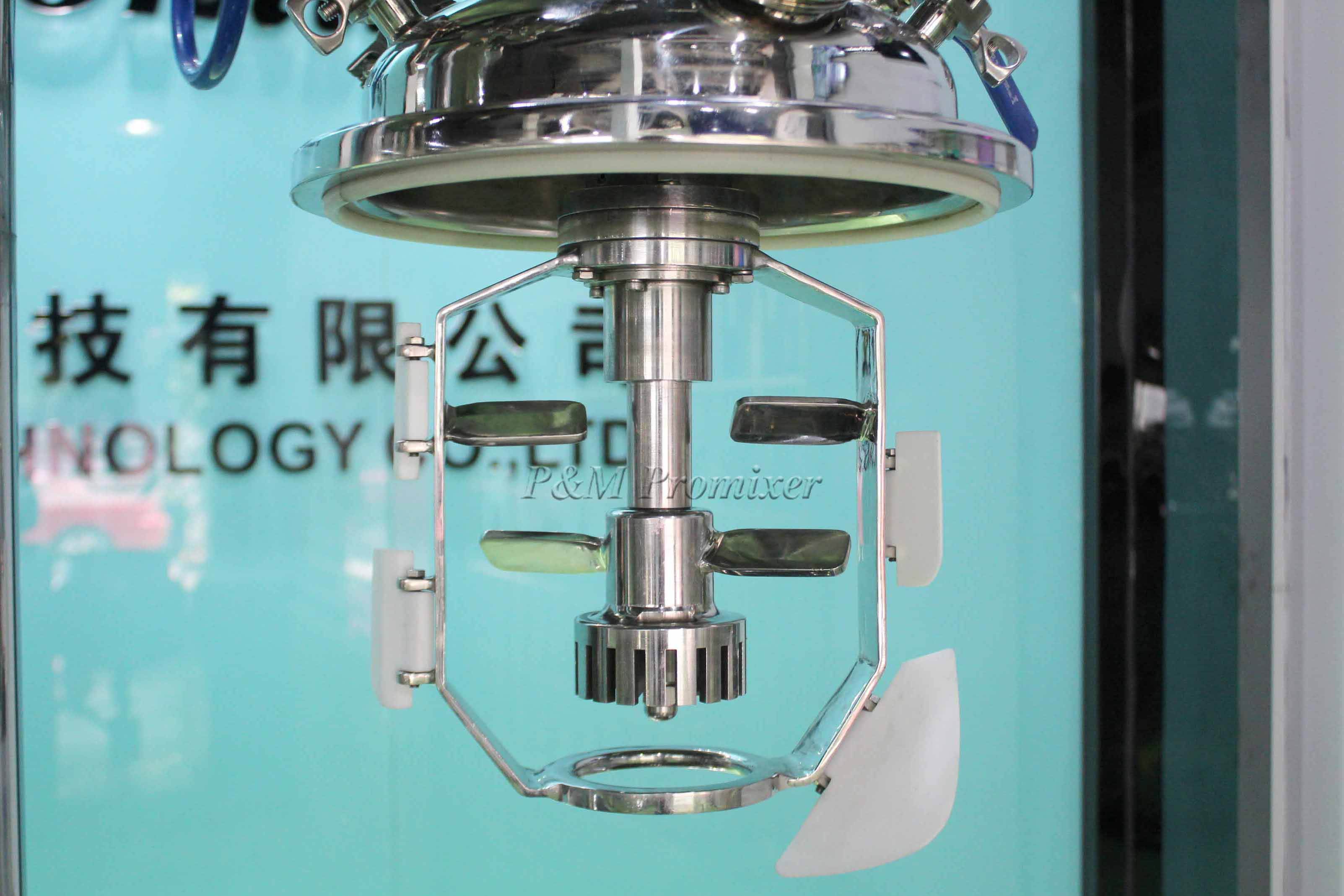

PVM-C 20L Vacuum Emulsifying Mixer (Bottom Homogenizer )

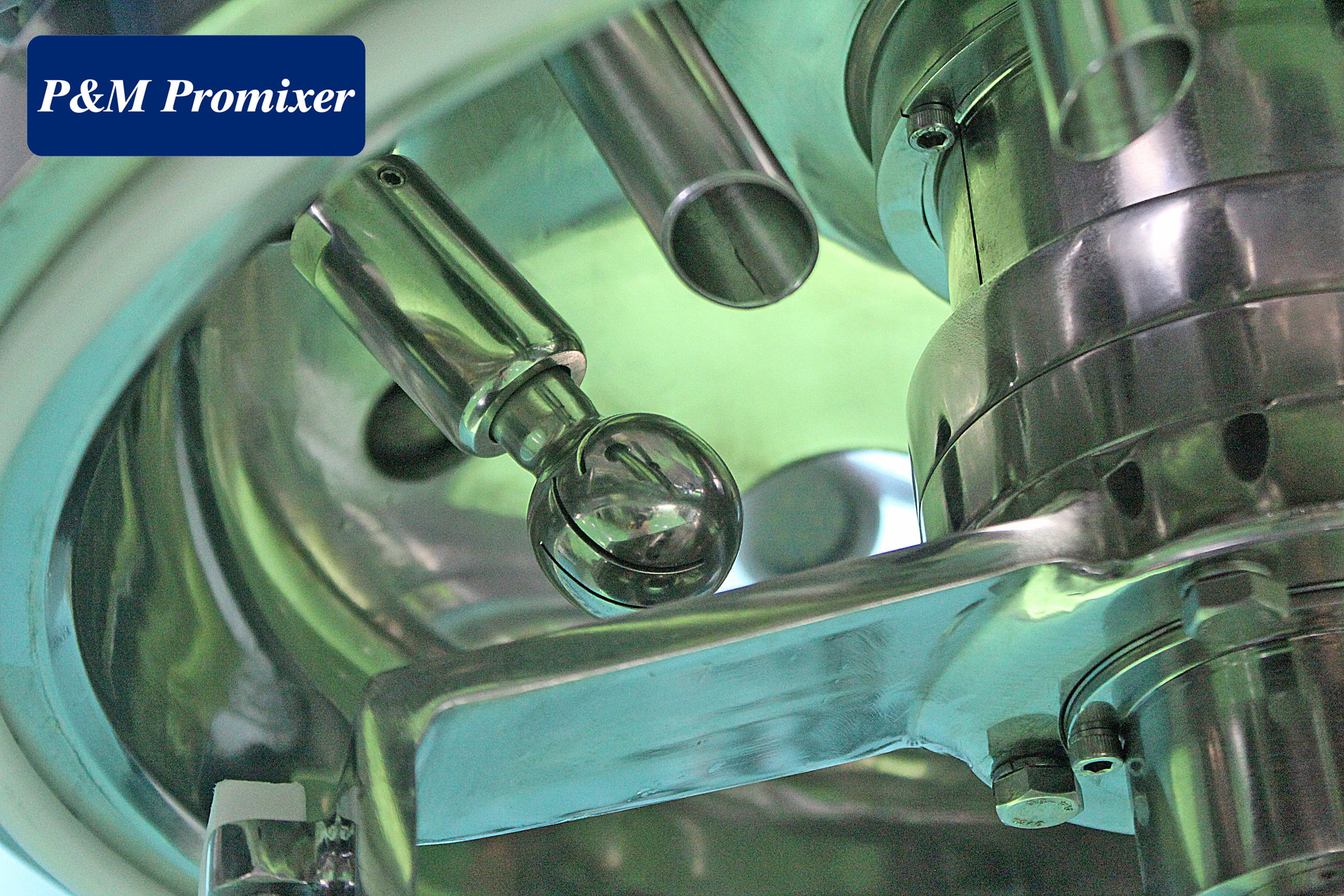

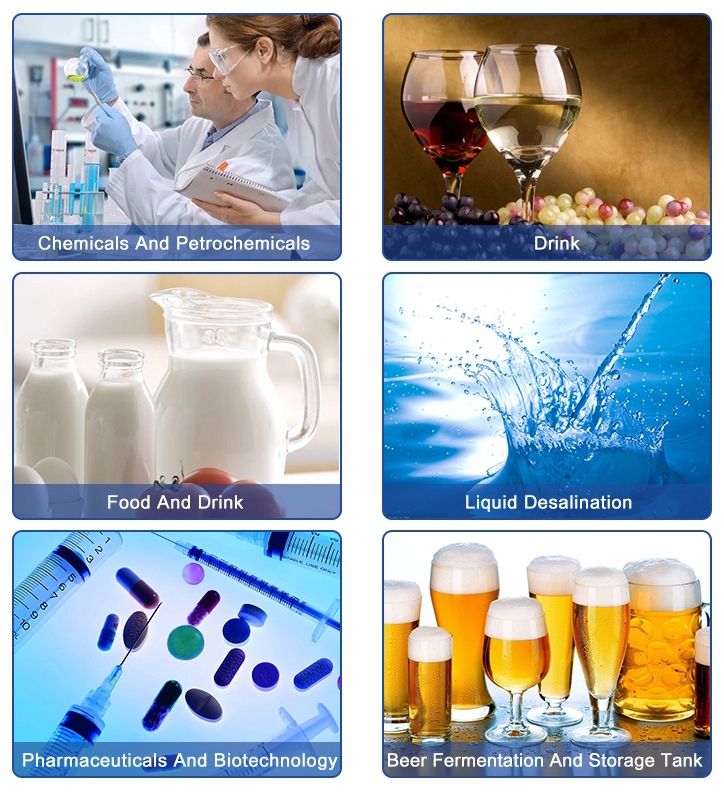

This device is mainly composed of Emulsifying tank, Water phase pot, Oil phase pot, Vacuum system, Electrical control panel, Lifting system(optional), Operation platform etc. Our main product — Hydraulic lifting high shear vacuum emulsifying mixer is in hot sale. It is designed on the basis of German technology, the first choice of cosmetic and pharmaceutical factories which manufacture high quality products. Its spare parts adopt international well-known brands, which ensure durable quality and operational stability of the machine. According to the feedback from our customers, this design style provides great satisfaction performance to them. 1. SIEMENS frequency converter for speed adjustment, which can meet production of different technology requirement. 2. The vacuum defoaming can make the materials meet the requirement of being aseptic.The vacuum material sucking adopted can avoid dust,especially for the powder products. 3. Mechanical sealing, good sealing effect and long working life. 4. The tank body and the pipes adopt mirror polishing, which fully conforms to GMP standards. 5. Material contact parts all use SUS316L stainless steel. 6. The heating method mainly include electric or steam heating for customer's choice. 7. The emulsifying pot lid can adopt hydraulic lifting system, easy to clean and the cleaning effect is more obvious, the emulsifying pot can adopt tilt discharge. Excellent mixing effect, (directly welding free of head corner) The heating element meets the European standard, with high safety performance. European standard's electic design and cabinet. Adopting famous electric brands from all over the world. Button panel, easy to operate, neatly arranged Spain technical design homogenizer, with fast speed up to 3000rpm/6000rpm The lid of the pot is equipped with the sanitary cleaning ball, which can rotate 360 degrees to facilitate cleaning ♦ SIEMENS frequency converter for speed adjustment, keeping the machine working stably and durably.

♦ Burgmann mechanical sealing, good sealing effect and long working life.

♦ The tank body and the pipes are mirror polished, which fully conforms to GMP standards.

♦ Material contact parts all use SUS316L.

♦ The heating method mainly include electrical or steam heating for customer's choice.

♦ Advanced PLC touch screen control is optional.

♦ The emulsifying tank lid can adopt hydraulic lifting system, easy to clean and the cleaning effect is more obvious, and the emulsifying tank can adopt tilting discharge.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||