Products |

Product Details

当前位置:

Home>

Product Details

10L Laboratory vacuum emulsifying mixer

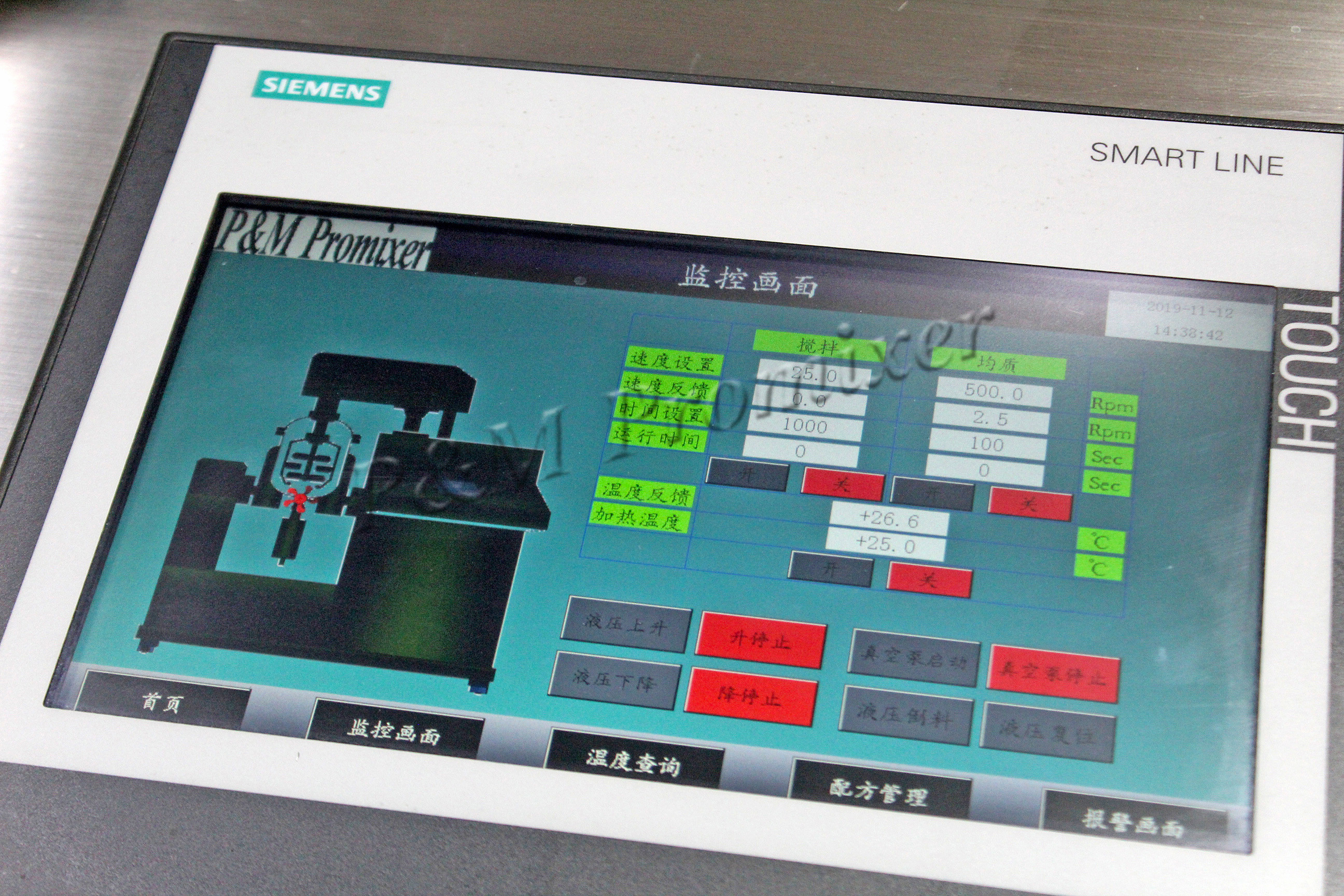

Vacuum Emulsifying Mixer means that when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distribute one or several phases to another continuous phases rapidly and evenly. The materials will be processed in the narrow space between stator and rotor by strong energy of motion produced by the mechanical effect. 1. SIEMENS frequency converter for speed adjustment, which can meet production of different technology requirement.

2. The vacuum defoaming can make the materials meet the requirement of being aseptic.The vacuum material sucking adopted can avoid dust,especially for the powder products.

3. Mechanical sealing, good sealing effect and long working life.

4. The tank body and the pipes adopt mirror polishing, which fully conforms to GMP standards.

5. Material contact parts all use SUS316L stainless steel.

6. The heating method mainly include electric or steam heating for customer's choice.

7. The emulsifying pot lid can adopt hydraulic lifting system, easy to clean and the cleaning effect is more obvious, the emulsifying pot can adopt tilt discharge. The lid of the pot is equipped with the sanitary cleaning ball, which can rotate 360 degrees to facilitate cleaning Excellent mixing effect, (directly welding free of head corner) Spain technical design homogenizer, with fast speed up to 3000rpm/6000rpm European standard's electic design and cabinet. Adopting famous electric brands from all over the world. SIEMENS PLC touch screen, With craft recipes and alarms Intelligent control The pot body is a three-layer structure, and the contact materials are made of SUS316L The product is mainly applied in such industries as daily chemical care products, Bio pharmaceutical industry, food industry, paint and ink, manometer materials, petrochemical industry. Printing and dyeing auxiliaries, pulp & paper, pesticide, fertilizer, plastic & rubber, electrics and electronics,fine chemical and industry, etc. The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||