1, the use of special types of frame-type wall mixing device, through the variable frequency converter to adjust the impact of mixing, can be 12-120 r / min speed range Italy speed. Steering from top to bottom as a clockwise steering, can adapt to a variety of viscosity materials, emulsification processing.

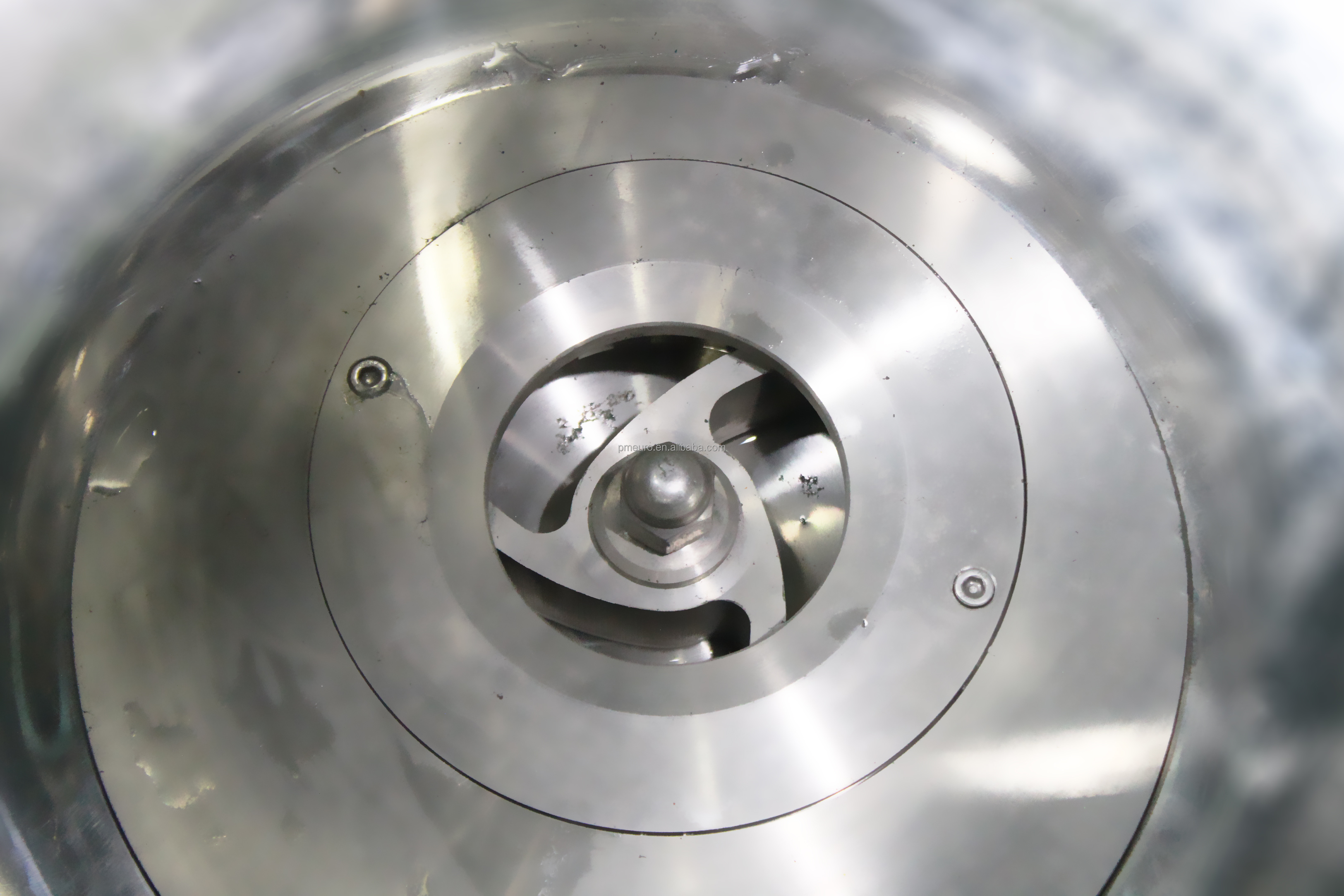

2, the use of special shear emulsion homogenization device, by the high-speed rotation of the rotor strongly inhaled materials and strong extrusion and shear. Homogenizer installed in the pot body .The center position, can make the material in the pot body naturally formed rolling and eliminate dead ends, so that the material can get higher quality homogenization.

3, supporting the special form of stainless steel discharge valve to ensure that the bottom of the pot does not leave dead ends, and further improve the homogeneous emulsion quality.

4, the motor through the frequency control device can be controlled by the frequency converter speed to meet the stability of the speed and strong torque.

5, the upper part of the seal using a single mechanical seal (sealed with glycerol).

6, homogeneous device sealed with a special design of the double-end mechanical seal and skeleton oil seal two seals, mechanical seal with cooling water circulation cooling.

7, emulsified pot pot for the three jacket structure, the pot and the material contact with the site are imported 304 and non-toxic harmless materials to ensure product quality. Outer packing Warm cotton to reduce energy consumption. The lid has a mirror and a scraper with a vacuum mirror, a perfume bucket, a filter, a vacuum pressure gauge, and so on.

8, all heating, cooling, mixing, homogeneous control buttons and temperature measurement instruments and other functions a

re concentrated in the control panel, easy to operate and reliable.